Want to connect manual workstations efficiently? Our compact AGVs are the perfect solution for your internal SMALL PARTS and SLC handling needs.

Autonomous mobile platforms

AGVs / AMRs for internal transportation and material handling

Wide range of ready-made AGV / AMR solutions

If a standard AGV doesn't meet the need, don't worry!

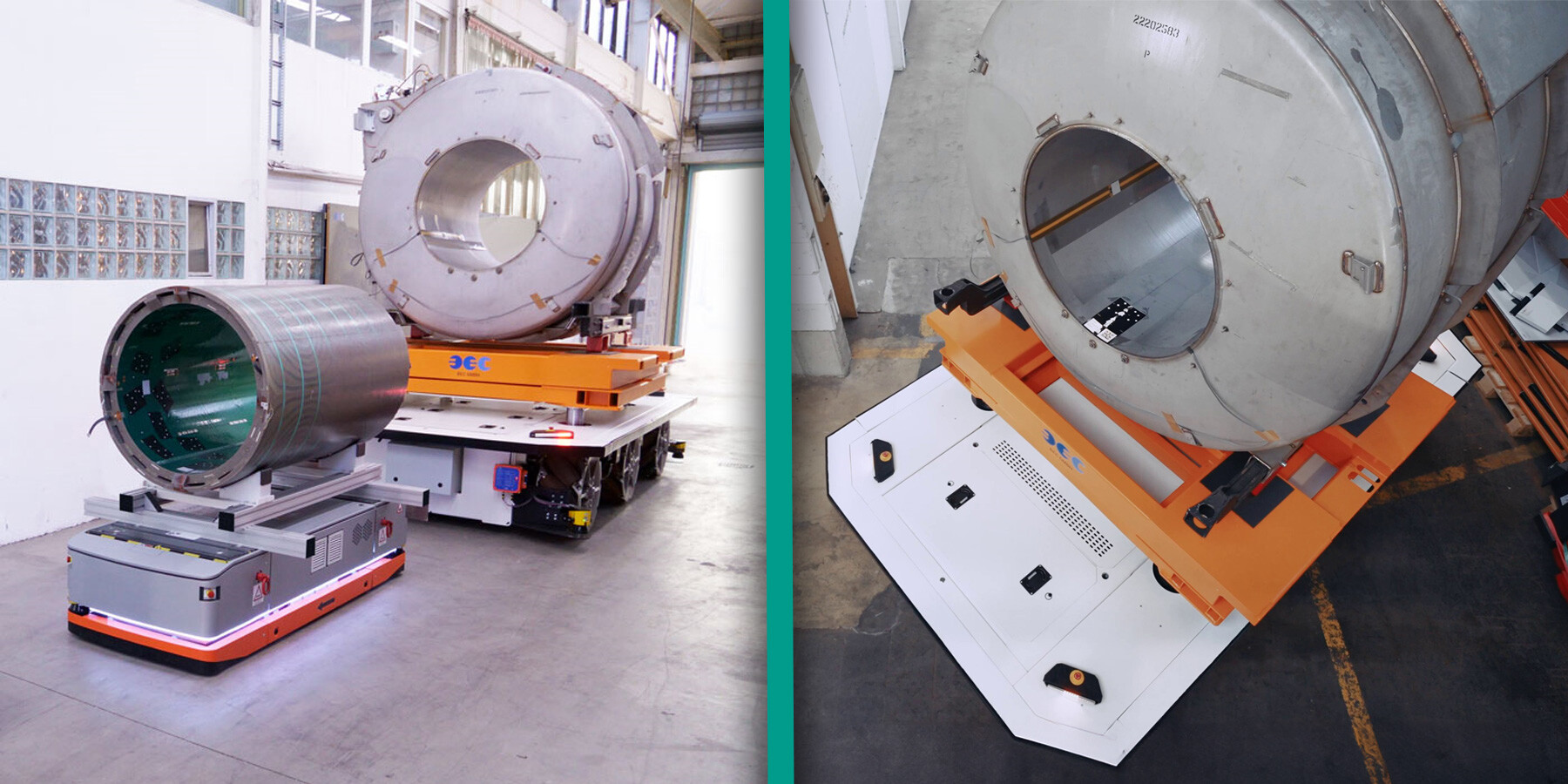

Even if your parts are LARGE and DIFFICULT TO HANDLE, we have the right AGV solutions to streamline your transportation needs.

Whatever your challenge, we have the right AGV platforms to autonomously move even HEAVY PAYLOADS, including transfer stations, superstructures and software interfaces.

With our High Precision Navigation (HPN), we are able to equip the AGVs to meet higher demands on the positioning accuracy of the AGV.

Small parts and SLC transportation

BEC Robotics specialises in transforming existing brownfield production facilities into advanced Industry 4.0 environments. We provide smart, innovative solutions that make automation accessible to small and medium-sized enterprises. With a focus on gradual and manageable integration, we typically start with individual machines and line connections, enabling step-by-step automation of existing processes. We offer customised automation solutions, including our own AGV, the BMP200 (datasheet), and AGVs from our partner companies. The BMP200 is designed so that we can flexibly extend it with suitable superstructures, making it suitable for a wide range of applications. Its compact size allows it to manoeuvre in tight spaces and is ideal for linking manual workstations. Each solution is optimised to meet the specific needs of our customers. Our goal is to enable Industry 4.0 standards for all production environments, regardless of their starting point.

> BMP200 datasheet download

Heavy load AGVs

Our mobile transport platforms effortlessly position heavy loads with precision, even in tight spaces. Moving XXL loads is easy with our heavy duty platforms. These heavy-duty AGVs navigate autonomously, lifting and moving loads of several tons with ease. Operations that were previously performed manually with cranes or other lifting systems can now be performed autonomously. Despite their large size and capacity, these systems operate safely and independently, integrating seamlessly into the work environment.

Efficient transport of large load carriers

BEC Robotics offers customized automation solutions, even in cases where there is no standard solution at first glance. We have developed an innovative solution for transporting large load carriers with the KUKA AGV KMP 1500P. The loaded pallets weigh more than 1.5 tons and are twice as long as the AGV itself. The considerable size and weight posed a particular challenge for automated transport and required additional safety measures for accelerating and braking the large mass and for maneuvering in narrow aisles and curves. To meet these requirements, a custom-designed load carrier with heavy-duty wheels was developed. This trolley extends beyond the outer dimensions of the AGV. Thanks to a precisely fitting coupling in the center of the frame, the trolley can be safely moved by the AGV without having to carry the entire load. The safety configuration of the AGV has been carefully adapted to the changes, and the navigation system has been adjusted accordingly to take into account the larger dimensions and enable optimal path planning.

FL1500 AGV Forklift from Stäubli

The Stäubli FL1500 is an ultra-compact 1.5-ton counterbalanced forklift AGV. Thanks to its modular design of counterbalanced weight and batteries the FL1500 can be configured with the right set-up for your industrial application. And thus FL1500 delivers a sustainable performance on your factory floor. Equipped with a hydraulic mono mast (with the prospect of developing an additional mast option), the counterbalance forklift AGV can not only move pallets and containers from floor to floor, but also stack them or store and retrieve them in racks. In addition, the FL1500 is highly maneuverable and has a small turning circle. BEC and Stäubli have been working together for some time in the field of heavy-duty AGVs, and the FL1500 counterbalanced truck is now part of this joint range.

Explore our full range of solutions for industrial automation

Simplified Intralogistics Automation with Rapid KUKA KMP 1500 P Deployment by BEC Robotics

Semicon Europa / Electronica 2024

Automation of Sterile Supply with KUKA KMR Cybertech | BEC Robotics