FABMOVER by BEC Robotics

Advanced AMR for Semiconductor Fab Automation

![]()

The FABMOVER is a high-performance Autonomous Mobile Robot (AMR) engineered by BEC Robotics to streamline manual handling tasks in semiconductor fabrication facilities, particularly within existing cleanroom environments. Leveraging KUKA's proven robotics technology, the FABMOVER delivers exceptional reliability, flexibility, and cleanroom compatibility, making it an ideal solution for advanced fab automation. Depending on the application and requirements, the FABMOVER is equipped with either the KUKA LBR iisy 6-axis robot or the KUMA LBR iiwa 7-axis robot.

By integrating the FABMOVER into your semiconductor manufacturing operations, you can achieve higher throughput, reduced contamination risks, and consistent, reliable performance in high-volume production settings.

Experience the future of cleanroom pod and cassette handling with the FABMOVER from BEC Robotics.

Key Features and Benefits:

+ Efficient Pod Handling

Automates the transport and management of wafer pods, reducing manual intervention and minimizing contamination risks.

+ Solutions for Automated Pod Opening and Closing:

Offers both stationary units and onboard modules mounted directly on the FABMOVER, facilitating fully autonomous end-to-end handling without manual intervention.

+ High Capacity and Navigation:

Equipped with up to eight onboard buffer slots, the FABMOVER adeptly navigates complex fab layouts, including narrow aisles, enhancing operational efficiency.

+ Scalable and Modular Design:

Adapts to evolving production needs with its flexible architecture, smart sensor technology, and modular functionality, ensuring a future-proof solution for optimizing material flow and labor resources.

Pod Handling

BEC Robotics provides advanced robotic pod handling solutions for semiconductor manufacturing, utilizing KUKA's industry-leading, cost-effective robotics and mobility technology. Our automated systems precisely handle wafer pods in cleanroom environments, streamlining loading, unloading and transfer processes. By eliminating manual tasks, we reduce errors, increase throughput and ensure consistent productivity. Designed to meet the rigorous demands of today's fabs, our solutions provide the reliability and flexibility needed to optimize high-tech manufacturing and maintain operational excellence. Contact us to improve your fab automation.

Efficient mobile robots for cassette handling in cleanrooms

BEC Robotics offers advanced mobile robotic cassette handling systems to meet the industry's need for cost-effective automation in cleanroom environments. The state-of-the-art mobile robotic systems can transport up to eight cassettes simultaneously, increasing operational efficiency and precision in semiconductor manufacturing. Designed to integrate seamlessly with existing fab infrastructure, the AMRs navigate complex layouts with remarkable flexibility. Equipped with advanced sensor and navigation technology, BEC Robotics' systems ensure safe, efficient operation while reducing manual handling and minimizing errors. Our scalable design adapts to evolving production needs, making them a future-proof solution for optimizing material flow and increasing productivity in semiconductor fabs.

SEMI E82 & E84 compliant software interfaces for semiconductor manufacturing

We provide state-of-the-art software interfaces to improve automation and integration in semiconductor manufacturing. Our solutions include SEMI E82-compliant interfaces for seamless connectivity to host systems and material control systems (MCS). We also offer custom interfaces to meet specific process control software requirements. Using the SEMI E84 interface, we ensure direct and efficient communication between machines and mobile robots, optimizing data exchange and operational coordination. Our software solutions streamline automation, improve system integration, and support robust communication to increase efficiency and productivity in advanced manufacturing environments.

Web-based AGV monitoring system

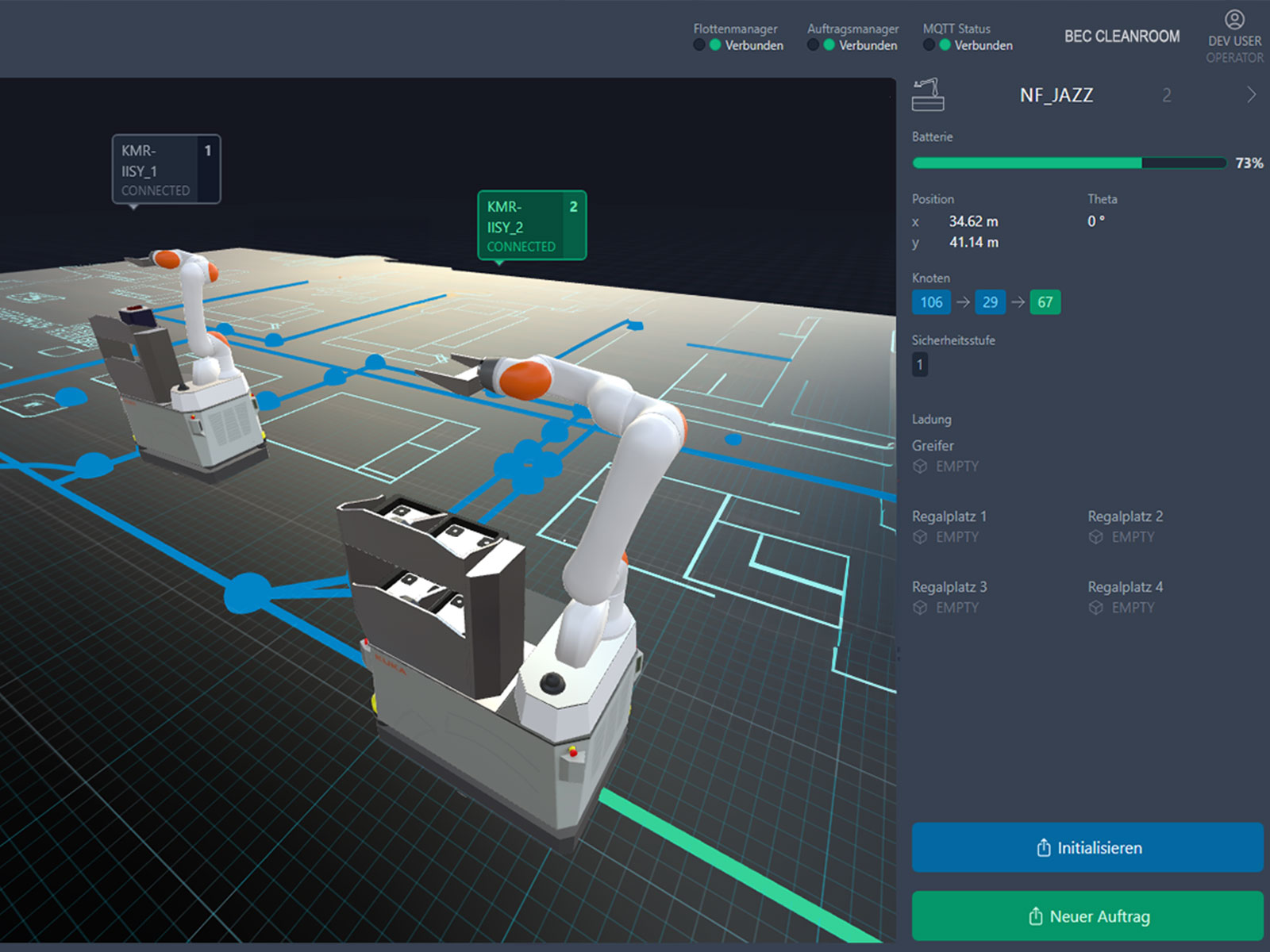

BEC's AGV Monitoring System is an easy-to-use, web-based application that runs on a variety of mobile devices. It provides real-time status information on system location, battery levels and load. Our intuitive graphical user interface makes troubleshooting easy and supports multi-user authentication for secure access. Stay informed with comprehensive job status monitoring and keep your intralogistics running smoothly and efficiently.

Explore our full range of solutions for cleanroom automation

Semicon Europa / Electronica 2024

Automation of Sterile Supply with KUKA KMR Cybertech | BEC Robotics